FARA: Why AVX Has A Shot At Army Scout

Posted on

WASHINGTON: Compared to its top competitors, aviation giants Sikorsky and Bell, design firm AVX is innovative but small, like a hornet fighting eagles. But a new partnership with the much larger L3, more time to refine its technology combined with changing Army priorities all give AVX a better chance than the last time it took on its far larger rivals five years ago.

“AVX has a deep bench of seasoned veterans of the helicopter industry and a broad team of partners,” said Mike Hirschberg, executive director of the independent Vertical Flight Society. “With the addition of major defense contractor L3, they pose a formidable contender for the FARA competition.”

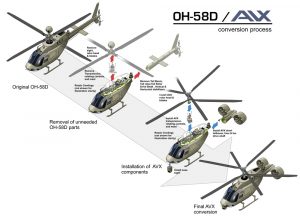

AVX’s proposal to turn the aging OH-58 Kiowa into a high-speed compound helicopter driven by twin ducted fans. The Army simply retired Kiowa instead, leaving a gap in its scout units that it’s now scrambling to fill with FARA, the Future Attack Reconnaissance Aircraft.

“I have a high regard for AVX as an innovative VTOL [Vertical Take-Off and Landing] engineering company,” agreed one retired Army aviator. “AVX has been perfecting their ducted fan technology for many years but have always lacked the ability to take a good idea into production. Now teamed with L3, they have filled the square.

“Their entry into the FARA competition must be taken seriously,” the former aviator continued, “though I would be concerned about their ability to meet expected performance goals. Ducted fans have traditionally been inefficient. Maybe AVX has fixed that problem.”

Ducted fans are the most visible trademark of AVX designs. Basically, they are rotors spinning inside a cylindrical cover, a propeller in a can. Arguably more efficient than conventional propellers and rotors at low speeds, but less efficient at high speeds, they’re used on the Navy’s LCAC hovercraft and off-the-shelf mini-drones. AVX, however, likes to put them on high-speed aircraft — from its Joint Multi-Role candidate, to its plan to upgrade the aging OH-58 Kiowa, to its Future Attack Reconnaissance Aircraft proposal today. They give AVX’s designs a distinctly futuristic look, echoing gunships like James Cameron’s Avatar.

For AVX CEO Troy Gaffey, however, the chief advantage of ducted fans is brutally down to earth. They’re less likely to chop people to pieces.

Yes, the ducted fans can vary the pitch of their blades in useful ways, making the aircraft more agile, Gaffey told me in an interview, and agility is crucial for the low-speed, low-altitude operations the Army envisions, ducking behind buildings and sneaking down streets to avoid Russian and Chinese anti-aircraft missiles. But that’s not this design feature’s most important virtue.

“We have used the ducts, not so much for propulsive efficiency or anything like that: We use the ducts primarily to protect personnel,” said Gaffey, a veteran of decades of military helicopter programs. “Running around at night in the dark — Army operations, probably half of them at least are in time of darkness … if you have an open propeller, someone could walk into it.”

For a company whose designs look like something out of a sci-fi film, AVX turns out to be pretty darn practical.

The L3 Advantage

Having L3 as a partner is the most obvious difference for AVX this time around. “They have the capability of handling very large aircraft,” Gaffey told me. “They’re responsible for the digital backbone for the aircraft, the so-called MOSA [Modular Open System Architecture] that allows you to plug-and-play mission equipment. They’re responsible for the cockpit displays to be able to fly the aircraft and also the weapons”: a 20mm cannon and missiles.

Make no mistake. AVX is still a long shot for the Future Attack Reconnaissance Aircraft (FARA), the Army’s new light scout, just as it was for the Joint Multi-Role Tech Demonstrator. The JMR program, for which AVX won awards to produce a design but not to build an actual aircraft, produced the Bell V-280 Valor and Sikorsky-Boeing SB>1 Defiant now vying to be the Army’s new mid-sized transport, the Future Long-Range Assault Aircraft (FLRRA). In stark contrast to AVX, Bell, Sikorsky, and Boeing all have long histories of and large facilities for manufacturing aircraft, plus cash reserves that let them pour much more money into building these two prototypes than the government ever paid for them.

But on FARA, for which AVX won a design contract last month — along with Bell, Sikorsky, Boeing, and another small company, Karem — AVX is partnered with L3 Technologies. On the authoritative Defense News list of the Top 100 defense contractors worldwide, L3 is no. 12, with $7.8 billion in 2017 revenues. Admittedly, that makes L3 only a seventh the size of Sikorsky’s parent company, No. 1 contractor Lockheed Martin, and just over one third the size of Boeing Defense (No. 5). But L3’s almost twice the size of Bell’s parent company, Textron (No. 20).

Just as important as deep pockets is manufacturing experience. L3 doesn’t build aircraft from scratch, unlike Sikorsky, Bell, or Boeing. But L3 has extensive experience with sensors, jammers, and communication, and it often installs those electronics on off-the-shelf aircraft it modifies extensively for military missions. The most recent high-profile example is a $1 billion contract to convert four Gulfstream 550s into electronic warfare aircraft for Australia. (It’s also providing electronics for Canada’s new frigate). Those modifications also require L3 to do a lot of flight-testing, another key area of expertise.

Upgrading aircraft with new electronics, of course, is not the same as building the airframe, engines, control surfaces, and so on in the first place. But Gaffey argues that AVX expertise helps fill that gap. AVX’s founders, Gaffey himself among them, were senior Bell engineers with decades of experience building both conventional helicopters and the V-22 Osprey tiltrotor, and AVX as a company has subcontracted for larger aviation firms.

“We’ve designed and built transmissions and rotors,” Gaffey said. “AVX has a lot of experience …. integrating the propulsion system, integrating the rotor and transmission, airframes.”

So, with that background, what aircraft design has AVX come up with for L3 to pack with high-tech electronics?

Let’s Get Technical

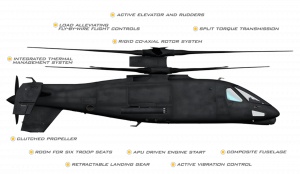

What AVX is offering for the Future Attack Reconnaissance Aircraft is called a compound helicopter. Essentially, it’s a hybrid of helicopter and propeller plane, with two sets of rotor blades on top — spinning in opposite directions, so you don’t need a tail rotor for stability — and a pusher propeller at the back, allowing it to reach much higher speeds than helicopter rotors alone allow.

Sikorsky (Lockheed) S-97 Raider design, a leading candidate for the Army’s Future Attack Reconnaissance Aircraft (FARA). (Click to expand). Note the exposed pusher propeller on the tail.

That’s the same basic approach used by Sikorsky, which has built a whole family of compound helicopters including the S-97 Raider — probably the leading contender for FARA so far — and the larger SB>1 Defiant, co-produced with Boeing for the Joint Multi-Role demonstration and a contender for FLRAA.

That said, there are many differences. The first is that Sikorsky’s aircraft physically exist and (after delays and accidents) are actually flying, while AVX’s are still on the drawing board. But there are three differences in design that Gaffey argues are advantages for AVX:

First, AVX’s dual pusher propellers are housed in its distinctive ducted fans to stop them killing anyone by accident. Sikorsky’s single pusher propeller is exposed, with a clutch mechanism to stop it spinning when the aircraft is on the ground. The clutch is a more elegant solution, as long as it doesn’t break down, because protective ducts add weight compared to a bare propeller. But the ducts also allow you to keep the props spinning the whole time you’re on the ground, instead of having to turn them off for safety’s sake, which Gaffey says means you can take off faster and get away quicker from a dangerous landing zone.

Second, the AVX design has wings for lift; Sikorsky’s X2 aircraft don’t. (Both aircraft do have large horizontal tailplanes for steering). AVX’s airplane-like wings take up to half the aircraft’s weight at high speeds, when the helicopter-style rotor blades become increasingly inefficient. Sikorsky, by contrast, gets all its lift from the rotor blades, which is more elegant than sticking on a pair of stubby wings, but requires some tricky engineering on the blades.

Finally, we get to the rotor blades. While both aircraft have a pair of rotors stacked one above the other on the same shaft (“coaxial”), Sikorsky’s are much closer together. This reduces drag and improves high-speed performance, Sikorsky says, but it also requires the rotors to be made of extremely rigid materials so they can’t vibrate so wildly they hit each other.

But one of the S-97 Raider prototypes crippled itself when its top and bottom rotors collided anyway, shredding each other into what the National Transportation Safety Board described as “a cloud of blade fragments and grey dust.” Fortunately this happened not in flight, which could have caused a fatal crash, but in a bad bounce maneuvering for takeoff. (Sikorsky says they have since corrected the software glitch responsible).

It’s also difficult to manufacture the rigid blades. Trying to scale up the process from the S-97 to the larger SB>1 Defiant delayed Defiant’s first flight for months.

By contrast, the AVX design uses conventional blade materials. It prevents the top and bottom rotors from hitting each other the old-fashioned way, by keeping them farther apart. It reduces the resulting drag by streamlining the rotor assembly. This approach is not as high-tech as Sikorsky’s ultra-rigid blades, but it’s also not as hard to build.

The recurring theme here — as one expert pointed out to me, anonymously — is that AVX’s take on a compound helicopter is generally less elegant, lower-tech, but also less risky than Sikorsky’s. Given the S-97’s accident and the SB>1’s delays, the Army might be happy to have a fall-back option if the Sikorsky designs prove too complex for the service’s tight budget and schedule. The Army wants FARA fast and for no more than $30 million apiece.

That said, both the Sikorsky and AVX varieties of compound helicopter are more complicated and technically risky than what Bell is offering: a regular vanilla helicopter without any high-speed features. Bell says their commercial Bell 525 Relentless has exceeded the speed the Army requires for FARA, 205 knots (235 mph), but it’s not clear how long the helicopter can sustain that pace.

Notably, no one we know of is offering a tiltrotor for FARA. While the Bell-Boeing V-22 Osprey excels at the long-haul missions the Marine Corps wants it for, Gaffey says, range matters less for FARA, which the Army wants to scout the front line rather than plunge deep into hostile territory. On the flipside, he said, the same broad wings and wide-set rotors that give tiltrotors their range advantage also make it hard for them to slip between buildings or other obstacles, which the Army sees as essential for FARA’s survival.

For the Army’s Future Long-Range Assault Aircraft, however, AVX might well offer a tiltrotor design, as it did for JMR years ago. “Depending on how they finally settle on their requirement, we could propose a tiltrotor or another compound,” Gaffey told me. He’s confident his company can do both.

Subscribe to our newsletter

Promotions, new products and sales. Directly to your inbox.