U.S. Army field artillery brigade print protective masks, fight COVID-19

Posted on

U.S. Army 17th Field Artillery ‘Thunderbolt’ Brigade Soldiers assigned to 308th Brigade Support Battalion joined the fight against the COVID-19 pandemic at Joint Base Lewis McChord, Washington, on April 1, 2020, as they began using additive manufacturing to produce personal protective equipment.

In response to increasing cases of COVID-19 around the world and corresponding shortages of masks across the United States, JBLM is using their resources by producing these PPE prototypes in support of our medical professionals that operate our medical facilities and for Soldiers performing COVID-19 missions.

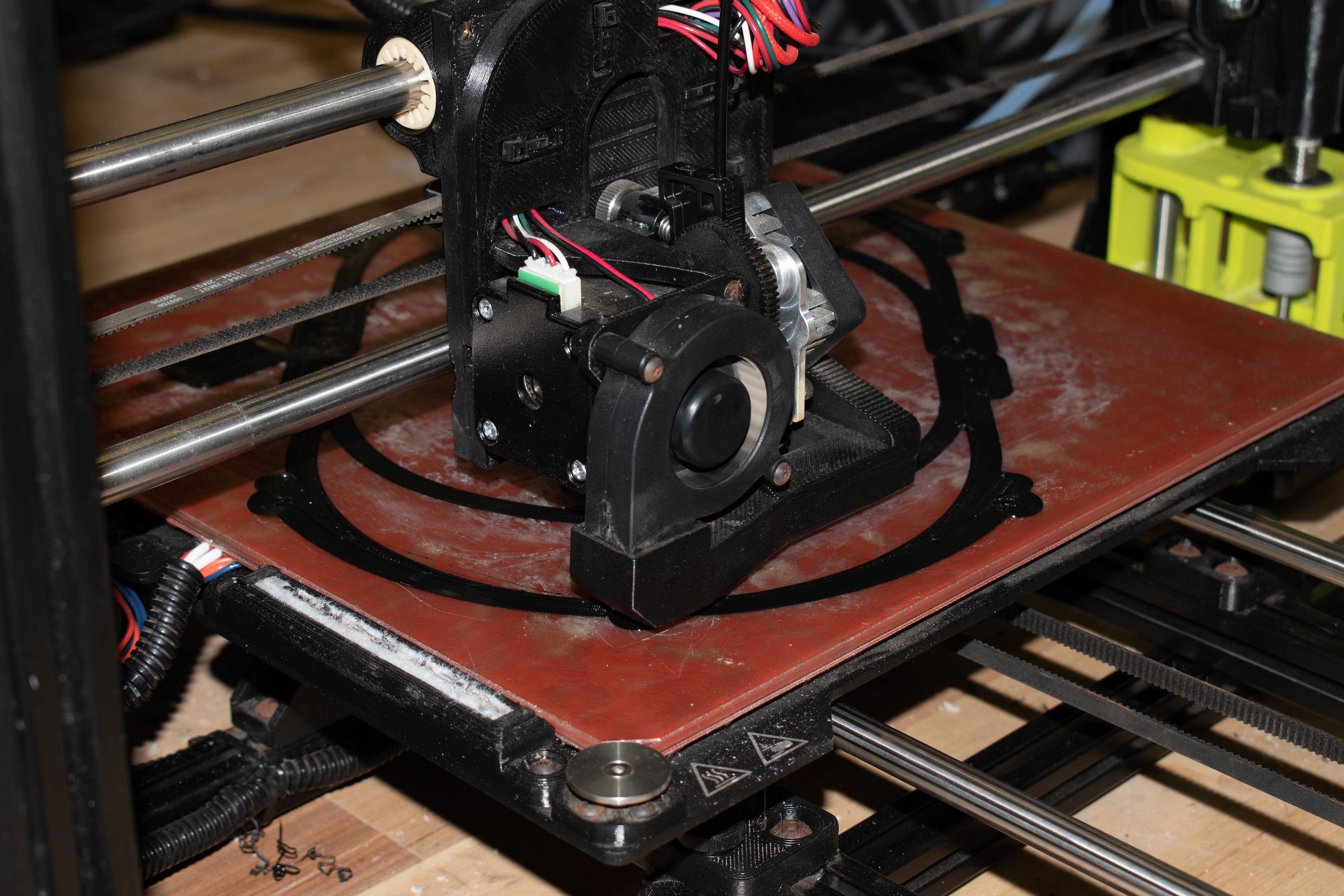

Using four 3-D printers — which commonly are used to create tools and parts for military vehicles — Thunderbolt Soldiers started production on personal protective equipment using the Rapid Fabrication via Additive Manufacturing on the Battlefield (R-FAB).

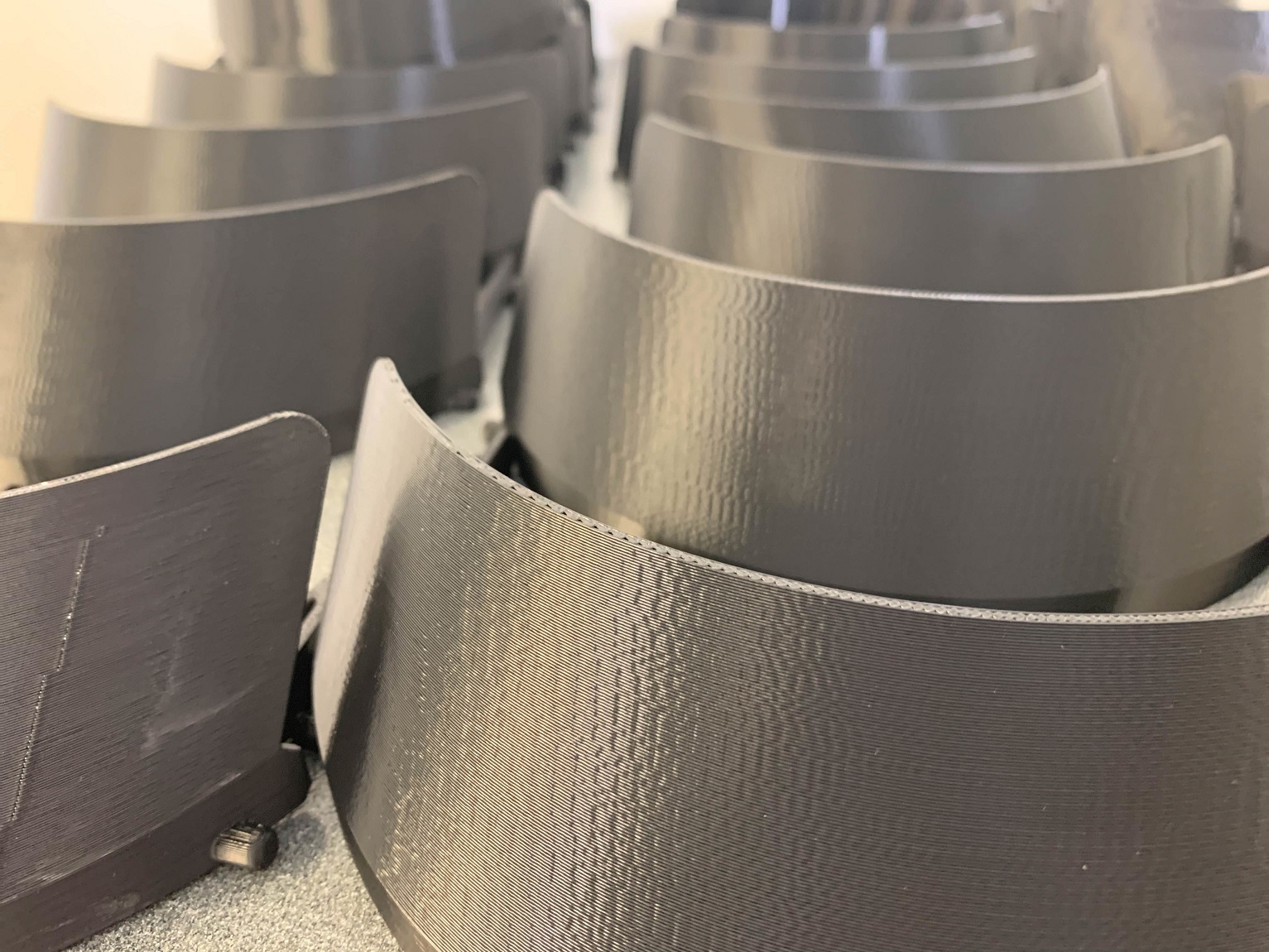

With this capability 308th BSB is capable of producing 24 face shields per day with a goal of 100 per week — leaving room to account for the time required to perform machine maintenance, power generator services and for failed part print productions.

“The design and initial guidance for the personal protective equipment was shared with me by a retired warrant officer assigned to 1st Special Forces Group (Airborne)” said Chief Warrant Officer 3 Richmond Minton, I Corps Logistics Officer. “We then took the design and shared it with our subordinate units across I Corps.”

When the initial guidance was given down to the subordinate units the Allied Trade Specialists, 91E, within the 308th BSB took on this challenge using the unit’s R-FAB.

“I’m not trying to make myself look good, I’m just trying to help people out,” said Chief Warrant Officer 2 Ivan Vazquez, an Allied Trade Warrant Officer with the 308th BSB, 17th FA BDE, whose usual focus is metal working and fabrication.

Thunderbolt Soldiers began printing the face shields using the approved program files and assembly instructions downloaded from the National Institutes of Health website.

“We are happy to be part of the team providing the solution,” said Lt. Col. Christina Lewis, commander of the 308th BSB. “This was definitely a combined effort amongst the Allied Trade Warrant Officers within 1st SFG (A), I Corps and 17th FA BDE. The Soldiers are gaining valuable experience from this while creating a product that can potentially help others all while utilizing equipment typically used during expeditionary missions.”

Minton will meet with experts from the University of Washington Medical Department COVID-19 research team April 7, to review face mask and filtering face-piece respirator (FFR) prototypes, review manufacturing processes, and review storage and shipment processes. All, to ensure efforts are in accordance with National Institutes of Health, Food and Drug Administration, and Veterans Affairs standards.

“This effort is important in two different ways,” said Minton. “First, it shows the capabilities that tactical units have and how they can provide a positive impact to Army wide concerns and requirements. Second, it highlights the capabilities that the Allied Trades career field possess and its ability to react to a need with a solution to assist commanders in mitigating risks to the force.”

“At the end of the day this highlights Soldiers taking care of Soldiers,” said Minton. “The Army has and always will be about caring for the person in front, behind and next to you.”

Subscribe to our newsletter

Promotions, new products and sales. Directly to your inbox.