U.S. Air Force base produces 3D-printed parts for America’s biggest military airplane

Posted on

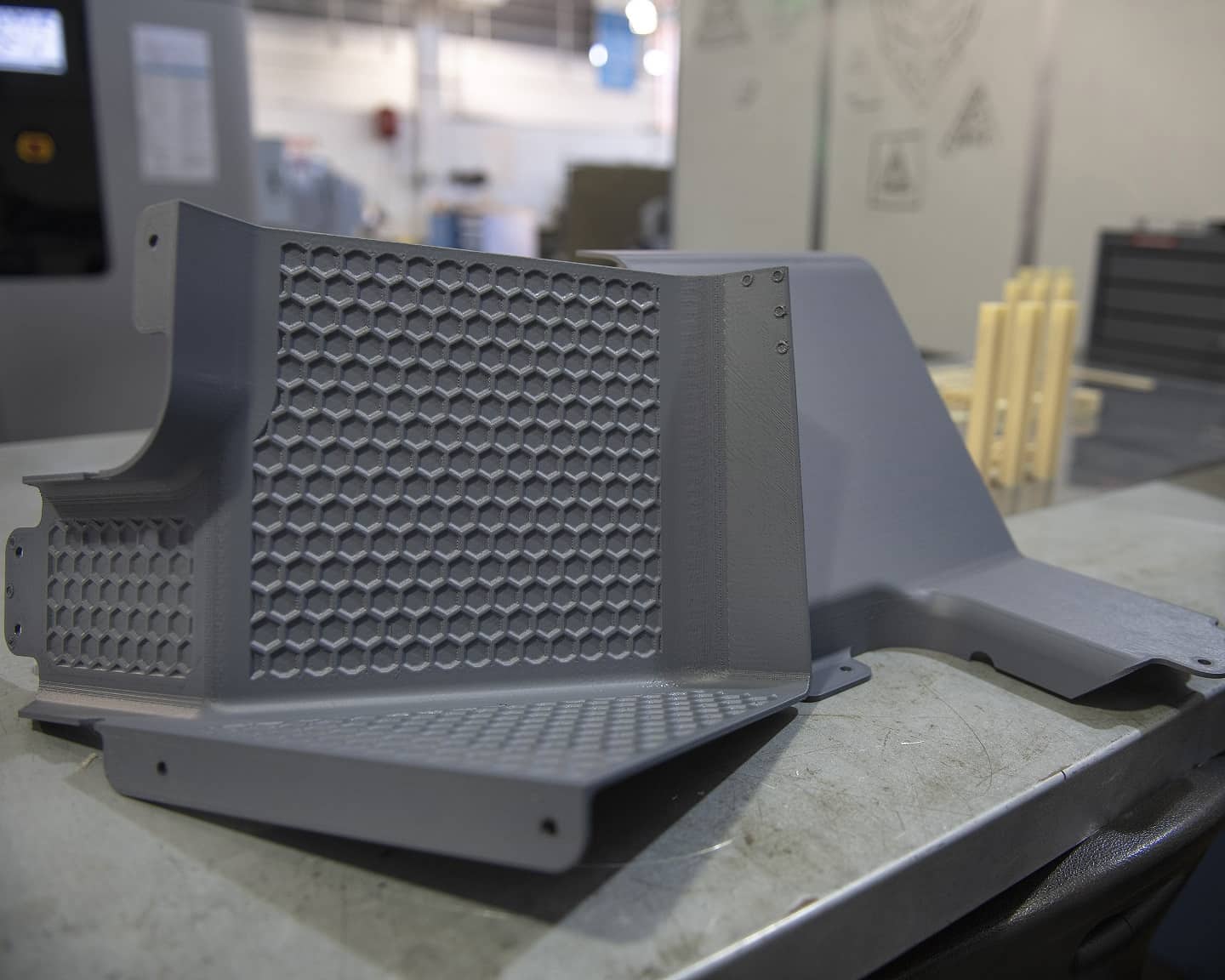

The U.S. Air Force Travis base in California for the first time produce 3D-printed aircraft parts for one of the largest airplanes in the world – C-5M Super Galaxy plane.

According to a statement released by the Air Force, the 60th Maintenance Squadron is the first field unit in the Air Force to be certified with an industrial-sized 3D printer that is authorized to produce nonstructural aircraft parts.

The Stratasys F900 3D printer, which is capable of printing plastic parts up to 36-by-24-by-36 inches, uses a material called Ultem 9085 that is more flexible, dense and stronger than typical plastic.

The printer, which is certified by the Federal Aviation Administration and the Air Force Advanced Technology and Training Center, offers new opportunities to create needed parts while saving time and money.

“It brings us a capability that we’ve never had before,” said Master Sgt. John Higgs, 60th MXS aircraft metals technology section chief. “There’s so many possibilities available to us right now. We’re just scratching the surface.”

Technicians are able to download blueprints from an online database that the University of Dayton Research Institute has approved.

“The Joint Engineering Data Management Information Control System is where we go to download already approved blueprints,” Higgs said. “Now, the University of Dayton Research Institute is working with the engineers to get those parts they developed into JEDMICS.”

The first approved project was printed on the Stratasys F900 Aug. 12 and will replace latrine covers on the C-5M Super Galaxy. Typically, parts that don’t keep the aircraft from performing their mission don’t have as high as a priority for replacement.

“The latrine covers we just printed usually take about a year from the time they’ve been ordered to the time they’ve been delivered,” Higgs said. “We printed two of the covers in 73 hours.”

Getting the printer operational was no easy task. It took eight months to get the system fully operational.

“There were facility requirements that had to be met, and then installation and certification processes to complete,” Higgs said. “After, we needed to decide who could operate the printer, then have a UDRI instructor certify them.”

Three members from the 60th MXS were chosen to be the first technicians trained in the Air Force for the initial certification. One of them, Tech. Sgt. Rogelio Lopez, 60th MXS assistant aircraft metals technology section chief, has been with the project since its inception.

“UDRI has not trained or certified anyone else at the field level except the three of us here at Travis Air Force Base,” Lopez said. “Now that we’re signed off on our training records, we’re the only ones who can operate, maintain and print on the Stratasys F900.”

Now with parts in production, all the hard work is paying off. There’s a new sense of urgency within the organization.

“It’s exciting because the Air Force is implementing new technology at the field level,” Lopez said. “The Air Force continues to encourage Airmen to be innovative by finding new ways to streamline processes and save resources.”

And since Travis AFB is the only field unit that is currently operational, requests from outside the organization are already coming in.

“We already have a list from the Air Force level to help them print and to backfill some supplies,” Higgs said. “This will ensure other bases can replace items sooner than expected with our help.”

Ultimately, the maintenance shop wants to use the printer for more than just aircraft parts.

“We have the capability to print parts on a production scale for a lot more customers,” Higgs said. “The overall goal is to generate products for every organization to support whatever needs they may have.”

Subscribe to our newsletter

Promotions, new products and sales. Directly to your inbox.